When your car starts showing strange symptoms—overheating, oil mixing with coolant, unexplained white smoke—it’s not just mechanical. It’s psychological. A car is more than a machine; it’s your daily companion. So when something serious like a cracked engine block might be the issue, understanding the signs and acting fast can save both money and stress.

Let’s break it down step-by-step, with clarity and confidence.

What Is a Cracked Engine Block?

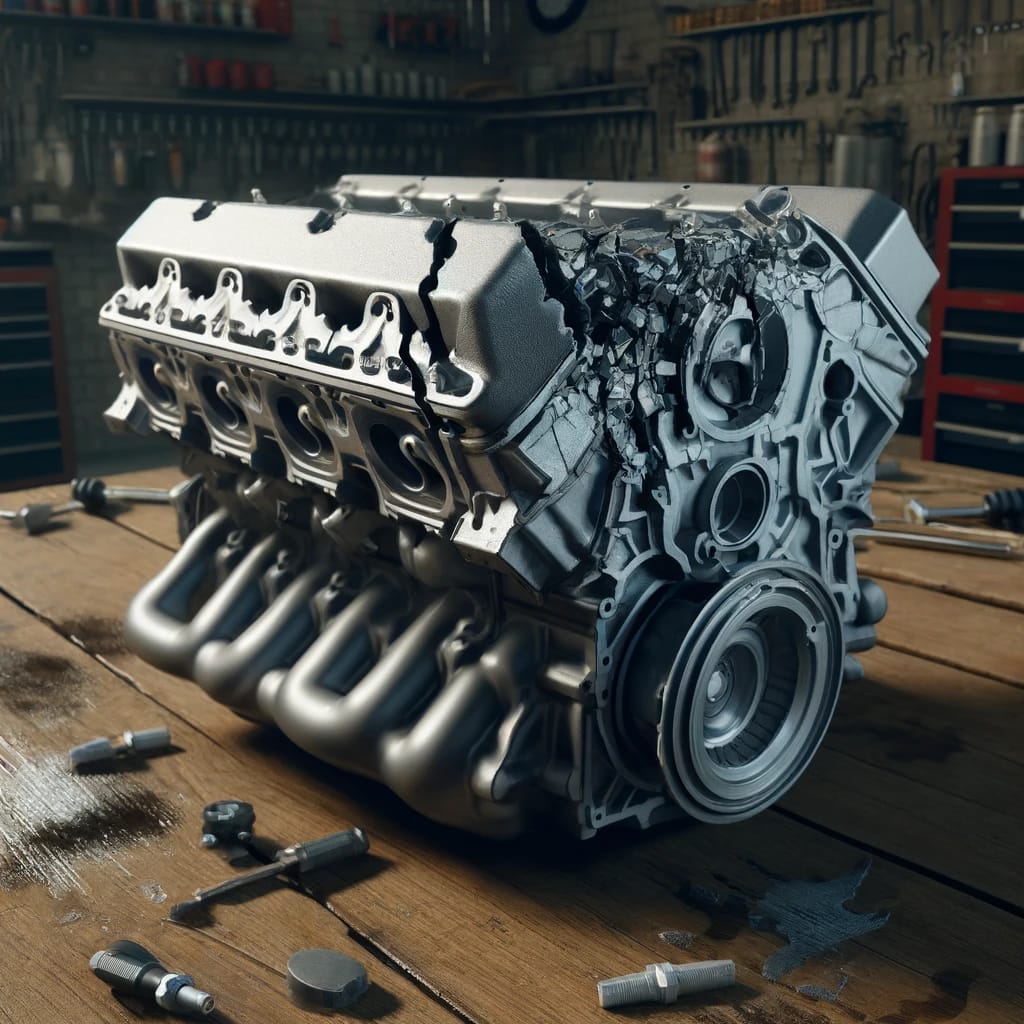

A cracked engine block is one of the most serious damages your engine can suffer. The engine block holds the cylinders and all components that power your car. When it’s cracked, fluids leak, performance drops, and long-term damage builds rapidly.

Broad match keywords: cracked engine block, engine block damage, diagnose engine block issues

What Causes an Engine Block to Crack?

- Severe overheating due to low coolant

- Freezing conditions without antifreeze

- Age and high mileage

- Manufacturing flaws in older models

These cracks often begin small, internally, and worsen over time. That’s why early detection of a cracked engine block is essential.

How to Know If Your Engine Block Is Cracked?

This is the moment where intuition meets observation. You don’t need to be a mechanic—you just need to know what symptoms to look for.

- White smoke from the exhaust

- Engine overheating even with full coolant

- Coolant in the oil or milky oil

- Loss of power and compression

- Visible cracks or leaks on the block

Check out this detailed guide on symptoms of Cracked Engine Block for expert insights.

Is It Safe to Drive With a Cracked Engine Block?

No. Driving with a cracked block is like running on a sprained ankle—it’ll only get worse. You risk complete engine failure, increased repair costs, and even danger on the road.

How to Confirm the Diagnosis?

Here are reliable methods:

- Pressure testing the cooling system

- Dye penetrant testing for surface cracks

- Engine teardown and inspection

- Compression and leak-down tests

These aren’t just mechanical tests—they are preventive actions to protect long-term vehicle health.

Can a Cracked Engine Block Be Repaired?

Yes—but it depends on the severity. Options include:

- Cold metal stitching

- Welding (for cast iron or aluminum)

- Engine block replacement

Most mechanics recommend replacement if the damage is extensive.

Prevention Tips That Actually Work

- Always use the correct coolant-to-water ratio

- Don’t ignore overheating

- Get regular oil and coolant checks

- Let your engine warm up in cold weather

Prevention is cheaper than repair—always.

Should You Fix It or Replace the Vehicle?

If the engine block damage is too high, and your car’s value is low, replacement may not be worth it. Evaluate:

- Cost of repair vs. car value

- Sentimental value

- Vehicle’s remaining lifespan

For related insights, check out USA Time Magazine’s guide on long-term car maintenance.

People Also Ask – FAQs (with Schema)

1. What are the early signs of a cracked engine block?

Early signs include overheating, white smoke, oil and coolant mixing, and rough idling.

2. Can a cracked engine block be fixed?

Yes, depending on severity—through welding, cold metal stitching, or replacement.

3. How much does it cost to repair a cracked engine block?

Repairs can range from $1,000 to $4,000+, depending on the vehicle and repair method.

4. Is it worth fixing a cracked engine block?

It depends on your vehicle’s value. For older cars, replacement might be more cost-effective.