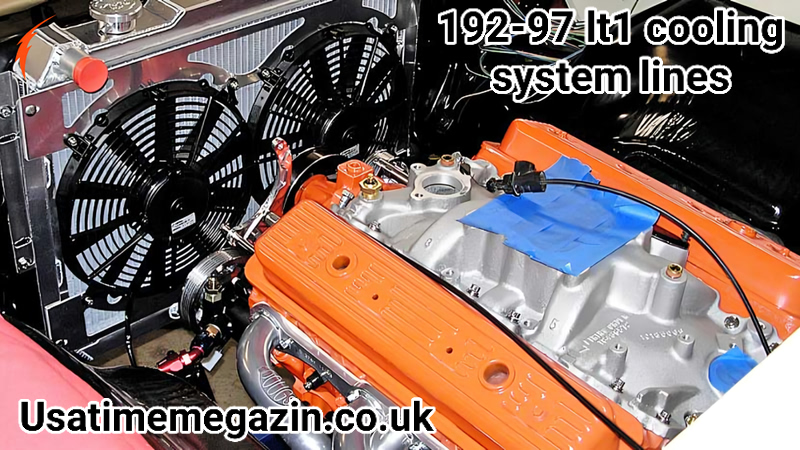

The cooling system is a critical component in any vehicle, ensuring that the engine maintains an optimal operating temperature. For those interested in classic cars, particularly those equipped with the LT1 engine produced between 192 and 1997, understanding the cooling system lines is vital. This article will delve into the intricacies of these cooling system lines, covering their function, design, common issues, and maintenance tips, ensuring you have a comprehensive understanding of how to keep your engine cool and functioning efficiently.

The Basics of the LT1 Engine

The LT1 engine, which was introduced in 1992 and continued in various forms until 1997, is a high-performance V8 engine known for its power and efficiency. It was widely used in various GM vehicles, including the Chevrolet Corvette and 192-97 lt1 cooling system lines Camaro. Understanding the cooling system in these vehicles is essential, as overheating can lead to severe engine damage. The cooling system is designed to absorb heat from the engine, dissipate it through the radiator, and maintain a stable temperature.

Components of the Cooling System

The LT1 cooling system comprises several key components:

Radiator: This component dissipates heat absorbed from the engine coolant.

Water Pump: It circulates coolant throughout the system, ensuring efficient heat transfer.

Thermostat: This device regulates coolant flow based on engine temperature.

Cooling System Lines: These lines transport coolant between various components, allowing for the transfer of heat.

Importance of Cooling System Lines

The cooling system lines are crucial as they ensure that coolant flows freely between the engine, radiator, and other components. Any leaks or 192-97 lt1 cooling system lines blockages in these lines can lead to overheating, which may result in engine failure. Understanding the layout and function of these lines can help in troubleshooting and maintaining your LT1 engine effectively.

Anatomy of 192-97 LT1 Cooling System Lines

The cooling system lines in the LT1 engine are designed to handle high pressure and temperature variations. Typically made of durable materials such as rubber or metal, these lines are engineered to withstand the harsh conditions of the engine bay.

Types of Cooling System Lines

Design Considerations

The design of these lines is critical for the performance and reliability of the cooling system. Factors such as diameter, length, and routing all 192-97 lt1 cooling system lines play a role in ensuring efficient coolant flow. Proper insulation and protection from abrasion are also important to prevent leaks and damage.

Common Issues with LT1 Cooling System Lines

Despite their robust construction, cooling system lines can encounter various issues over time. Understanding these problems can help you identify and address them before they lead to more significant engine damage.

Leaks

One of the most common issues 192-97 lt1 cooling system lines with cooling system lines is leaks. These can occur due to wear and tear, exposure to heat, or damage from road debris. A leak in the upper radiator hose, for example, can lead to a rapid loss of coolant, causing the engine to overheat.

Cracks and Wear

Over time, the rubber in cooling system lines can dry out and crack, particularly in older vehicles. This deterioration can result in coolant seeping out and affecting the overall efficiency of the cooling system. Regular inspection of the hoses is crucial, especially in vehicles over a decade old.

Blockages

Debris and sediment can accumulate within the cooling system lines, leading to blockages that restrict coolant flow. This can result in localized overheating, especially if the blockage occurs near the engine. Regular flushing of the cooling system can help prevent this issue.

Connection Failures

The connections between cooling 192-97 lt1 cooling system lines system lines and components are also susceptible to failure. Corrosion or improper installation can lead to leaks at these junctions. It’s essential to ensure that all connections are secure and free of corrosion.

Maintenance Tips for LT1 Cooling System Lines

Proper maintenance of your LT1 cooling system lines can extend their lifespan and improve engine performance. Here are some practical tips to keep your cooling system in top condition.

Regular Inspections

Routine inspections of cooling system lines should be part of your vehicle maintenance regimen. Look for signs of wear, such as cracks, bulges, or leaks. Addressing small issues before they become significant problems can save time and money.

Replace Old Hoses

If your LT1 engine is equipped with original hoses, consider replacing them, especially if they show signs of age. Rubber hoses typically have a lifespan of 5 to 10 years, depending on usage and conditions. Investing in high-quality replacement hoses can ensure reliable performance.

Flush the Cooling System

Flushing the cooling system every 192-97 lt1 cooling system lines couple of years can help remove debris and prevent blockages. This process involves draining the old coolant, cleaning the system, and refilling it with fresh coolant. It’s a simple yet effective way to maintain your engine’s cooling efficiency.

Use the Right Coolant

Using the correct type of coolant for your LT1 engine is essential for optimal performance. Ensure that the coolant is compatible with your vehicle’s materials and designed for high-performance applications. This can help prevent corrosion and extend the life of the cooling system.

Monitor Temperature Gauges

Always pay attention to your vehicle’s temperature gauge. If it indicates overheating, take immediate action to diagnose and resolve the issue. Ignoring warning signs can lead to severe engine damage, which can be costly to repair.

Troubleshooting Cooling System Line Issues

If you suspect issues with your LT1 cooling system lines, here are some steps to troubleshoot the problem effectively.

Check for Leaks

Start by inspecting all cooling system lines for visible leaks. Look for wet spots or coolant stains, particularly around the connections and junctions. If you find a leak, determine whether it’s coming from a hose or a connection.

Pressure Test

Conducting a pressure test can help identify leaks that are not immediately visible. This involves pressurizing the cooling system and monitoring for drops in pressure, which indicate a leak. If you’re unsure how to perform this test, consult a professional mechanic.

Inspect for Blockages

If your engine is overheating but there are no visible leaks, check for blockages. You can do this by disconnecting the hoses and inspecting them for debris. A thorough cleaning of the cooling system may be necessary if blockages are found.

Monitor Coolant Levels

Keep an eye on your coolant levels. A sudden drop in coolant can indicate a leak or internal engine problem. Regularly topping off the coolant without addressing the underlying issue can lead to more severe damage over time.

Conclusion

Understanding the 192-97 LT1 cooling system lines is essential for anyone who owns a vehicle equipped with this engine. Regular maintenance, including inspections and timely replacements, can prevent overheating and ensure that your engine operates efficiently. By being proactive and aware of potential issues, you can enjoy the performance benefits of your LT1 engine while minimizing the risk of costly repairs.

Also read this; trader-joes-food-codes-database-list-exce

FAQs About LT1 Cooling System Lines

What materials are LT1 cooling system lines made of?

LT1 cooling system lines are typically made from durable rubber or metal, designed to withstand high temperatures and pressures.

How often should I inspect my cooling system lines?

Regular inspections should be part of your routine maintenance, ideally every few months, or at least annually.

What signs indicate a problem with cooling system lines?

Look for signs such as coolant leaks, cracks in the hoses, or abnormal temperature readings on your engine’s gauge.

Can I replace cooling system lines myself?

Yes, if you have basic mechanical skills and the right tools, you can replace the cooling system lines yourself. However, if you’re unsure, it’s always best to consult a professional.

What type of coolant should I use in my LT1 engine?

Use a coolant that is compatible with your LT1 engine and designed for high-performance applications to ensure optimal performance and prevent corrosion.