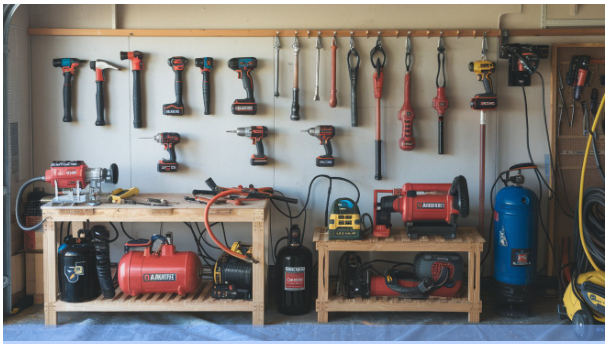

For professionals in fields like automotive repair, construction, and carpentry, the right air tools can be game-changers in efficiency and effectiveness. Air-powered tools, also known as pneumatic tools, offer high power, versatility, and durability, making them ideal for a wide range of tasks. Here’s a look at ten essential air tools every professional should have in their toolkit.

1. Air Impact Wrench

An air impact wrench is a powerhouse tool that generates high torque to loosen or tighten nuts and bolts quickly. Ideal for automotive work and heavy-duty construction projects, impact wrenches make removing or securing lug nuts, bolts, and fasteners a breeze. The air-powered version of this tool delivers superior torque and is lighter than electric versions, making it perfect for repetitive use.

- Key Features: High torque, variable speed control, and a durable build.

- Use Cases: Automotive repair, tire changing, and assembling large machinery.

2. Air Ratchet Wrench

An air ratchet wrench is essential for tighter spaces where an impact wrench might be too large. While it doesn’t deliver as much torque as an impact wrench, it provides just enough power for smaller bolts and nuts, especially in areas that are difficult to reach. Its compact design and smooth operation make it invaluable in automotive repair and machinery maintenance.

- Key Features: Compact, high-speed operation, and lightweight.

- Use Cases: Automotive repair, machinery assembly, and general repairs.

3. Air Hammer

Air hammers are incredibly versatile, enabling users to chip, cut, and carve various materials like metal, stone, and even wood. Equipped with different attachments, an air hammer is suitable for jobs that require chipping rust, cutting metal, or even carving designs into surfaces. Professionals in the automotive, construction, and metalworking industries frequently use this tool for tasks that require precision and power.

- Key Features: Interchangeable bits, high-impact force, and variable speed.

- Use Cases: Metalworking, construction, and stone carving.

4. Pneumatic Die Grinder

A die grinder is a high-speed tool primarily used for polishing, grinding, and smoothing rough edges. It’s commonly used in metalworking and automotive fields for tasks like shaping metal, removing rust, and polishing surfaces. The pneumatic version offers greater power and speed, especially when working with tough materials.

- Key Features: High-speed rotation, various grinding attachments, and a compact design.

- Use Cases: Metal shaping, polishing, and surface preparation.

5. Air Drill

An air drill offers a lightweight, powerful alternative to electric drills. Professionals favor air drills for repetitive tasks as they can reduce fatigue due to their lower weight. They’re often used in automotive repair, woodworking, and metalworking, making them a versatile addition to any toolkit. With adjustable speeds, an air drill can tackle everything from drilling metal and wood to screw-driving.

- Key Features: Lightweight, variable speed, and ergonomic design.

- Use Cases: Automotive repairs, woodworking, and general-purpose drilling.

6. Air Sander

An air sander is essential for anyone working with wood, metal, or paint. With various sanding pads, an air sander can handle different materials and is excellent for creating a smooth finish. The pneumatic version tends to offer greater speed and a more consistent finish, making it preferable for professionals in woodworking, auto body repair, and painting.

- Key Features: Variable speed, different pad types, and smooth operation.

- Use Cases: Woodworking, auto bodywork, and paint preparation.

7. HVLP Spray Gun

For professionals in painting, automotive finishing, or woodworking, an HVLP (High Volume Low Pressure) spray gun is invaluable. These spray guns provide a smooth, even coat with minimal overspray, which not only saves material but also reduces the mess. HVLP spray guns are commonly used for applying finishes to furniture, cars, and large surfaces where a precise, clean application is needed.

- Key Features: Fine mist spray, adjustable pattern control, and efficient material use.

- Use Cases: Auto painting, furniture finishing, and large surface painting.

8. Air Cut-Off Tool

An air cut-off tool is compact but powerful, ideal for cutting through metal, plastic, or bolts with precision. It’s used extensively in automotive and metalworking industries to trim parts to size or cut through stubborn bolts and metal sheets. Unlike larger cutting tools, an air cut-off tool offers the speed and control needed for small, precise cuts.

- Key Features: High RPM, compact size, and ergonomic grip.

- Use Cases: Automotive repair, metal fabrication, and small cutting jobs.

9. Air Chisel

An air chisel is similar to an air hammer but is more suited to detailed chiseling tasks, like cutting through metal panels or removing tiles. With various chiseling attachments, an air chisel can shape and remove material with efficiency. It’s especially popular in automotive body shops and among demolition crews for its ability to tackle dense materials without strain.

- Key Features: High-impact force, variable speed, and multiple attachments.

- Use Cases: Demolition, automotive bodywork, and construction.

10. Air Blow Gun

Though simple, an air blow gun is an essential tool for any professional workspace. It allows for quick and efficient cleaning of dust, debris, and metal shavings from surfaces and tools. In industries like automotive repair, woodworking, and metalworking, an air blow gun helps maintain a clean workspace, which is crucial for accuracy and safety.

- Key Features: Easy to use, durable, and adjustable air pressure.

- Use Cases: Cleaning workspaces, clearing debris from machinery, and drying surfaces.

Why Air Tools?

Air tools are preferred in professional settings due to their durability, high performance, and reliability under continuous use. Unlike electric tools, pneumatic tools generally run cooler and can often be used in environments where sparks or heat could be a safety hazard. They are also less prone to overheating, which is an advantage during extended work periods.

Choosing the Right Air Compressor

For professionals working with multiple air tools, a high-quality air compressor is essential. The compressor’s power and capacity should be compatible with the requirements of the tools, as each has unique demands for airflow and pressure. Tools like impact wrenches and spray guns may require higher air pressure, so selecting an air compressor with a PSI (pounds per square inch) rating and CFM (cubic feet per minute) that meets your most demanding tool is crucial.

Tips for Maintaining Your Air Tools

To ensure the longevity of air tools, regular maintenance is key:

- Lubrication: Regularly lubricate moving parts to prevent wear and rust.

- Inspect Hoses: Check for leaks in hoses and connectors, which can reduce efficiency.

- Clean After Use: Clear any dust or debris to prevent clogging and ensure smooth operation.

- Proper Storage: Store in a dry place to avoid rust and corrosion.

Conclusion

These ten air tools cover a wide range of applications, making them essential for professionals in various trades. From high-powered impact wrenches to precise air blow guns, each tool offers unique benefits that can make work more efficient and effective. For any professional looking to invest in tools that stand the test of time and heavy use, these air-powered essentials are well worth the investment. Whether you’re working in automotive repair, construction, or metalworking, the right air tools can elevate your work to a professional standard.