In today’s construction and electrical industries, ensuring safety and compliance with stringent fire regulations is paramount. Among the array of cables available, the FP200 cable stands out as a trusted choice for fire protection in wiring installations. Designed to meet rigorous safety standards and equipped with advanced fire-resistant properties, fp200 cable provide a reliable solution for both commercial and residential applications.

Understanding FP200 Cable

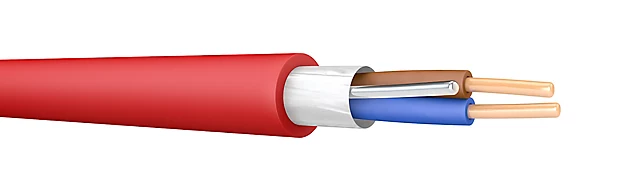

FP200 cables and bs6004 are specifically engineered to resist fire propagation and maintain circuit integrity during a fire incident. These cables are constructed using specialized materials that offer exceptional fire resistance, ensuring they do not contribute to the spread of flames or emit harmful smoke and gases. This makes them ideal for use in environments where fire safety is critical, such as hospitals, schools, offices, and public buildings.

Key Features and Benefits

- Fire Resistance: FP200 cables are manufactured with materials that have a high resistance to fire, ensuring they can withstand elevated temperatures without compromising safety.

- Compliance: These cables comply with stringent international standards for fire safety, including BS 7629-1 and BS EN 50200, which define their performance under fire conditions.

- Durability: They are durable and robust, capable of maintaining their structural integrity even in adverse conditions, thereby reducing the risk of electrical failures due to fire.

- Low Smoke Emission: During a fire, FP200 cables emit minimal smoke, contributing to improved visibility and facilitating safe evacuation procedures.

Applications of FP200 Cable

FP200 cables find widespread use across various industries and applications:

- Commercial Buildings: They are extensively used in commercial buildings to ensure the safety of occupants and protect valuable assets.

- Residential Complexes: In residential settings, FP200 cables provide peace of mind by enhancing fire safety measures within homes.

- Industrial Facilities: Industries utilize FP200 cables to safeguard critical equipment and maintain operational continuity during fire incidents.

- Transport Infrastructure: They are employed in transportation infrastructure, such as airports and railway stations, to uphold stringent safety regulations.

Installation and Maintenance

Proper installation and regular maintenance are crucial to maximize the performance and longevity of FP200 cables:

- Installation: Ensure that cables are installed by qualified professionals following manufacturer guidelines and local regulations to maintain fire safety standards.

- Inspection and Testing: Regular inspections and testing help identify potential issues and ensure that FP200 cables continue to meet fire safety requirements over time.

- Replacement: Replace cables if they show signs of wear or damage to uphold fire protection capabilities and prevent potential hazards.

Choosing FP200 Cable for Fire Safety

When selecting FP200 cables for fire protection, consider the following factors:

- Regulatory Compliance: Verify that cables comply with relevant fire safety standards and regulations applicable to your region.

- Application Specificity: Choose cables that are suitable for the specific environmental conditions and operational requirements of your installation.

- Manufacturer Reputation: Opt for cables from reputable manufacturers known for producing high-quality, reliable products that adhere to industry standards.

Maintenance and Care

Maintaining FP200 cable is essential to ensure its longevity and continued fire resistance:

- Inspection: Regular visual inspections to check for signs of wear, damage, or degradation.

- Cleaning: Keeping cables free from dust and debris that could potentially compromise their performance.

- Replacement: Prompt replacement of cables that show signs of wear or damage to maintain optimal fire protection.

Environmental Considerations

FP200 cable is designed to withstand various environmental conditions:

- Temperature Resistance: Capable of operating in a wide range of temperatures, from extreme cold to heat.

- Moisture Resistance: Some variants are designed to resist moisture and humidity, making them suitable for outdoor or damp environments.

- Chemical Resistance: Provides resistance to certain chemicals, enhancing its suitability for industrial applications where exposure to corrosive substances may occur.

Innovation and Future Trends

The evolution of FP200 cable continues with advancements in materials and manufacturing processes:

- Enhanced Materials: Research into new insulation materials to improve fire resistance and performance.

- Smart Technologies: Integration of smart features such as monitoring systems for real-time performance tracking and early fault detection.

- Sustainability: Emphasis on eco-friendly materials and manufacturing processes to reduce environmental impact.

Regulatory Compliance and Standards

FP200 cable is subject to rigorous testing and certification to meet international standards:

- Global Standards: Conforms to standards such as BS 7846, EN 50200, and local regulations specific to fire safety and electrical installations.

- Certification Marks: Look for certification marks from accredited testing laboratories to ensure compliance with safety standards.

Challenges and Considerations

Despite its benefits, FP200 cable does present certain challenges:

- Cost: Initial costs may be higher compared to conventional cables due to its specialized construction and fire-resistant properties.

- Installation Complexity: Requires skilled installation to ensure proper routing, fixing, and testing, adding to overall installation time and cost.

- Compatibility: Consideration of compatibility with existing electrical systems and equipment to ensure seamless integration and performance.

Case Studies and Real-World Applications

Exploring real-world examples where FP200 cable has been successfully implemented:

- Emergency Services: Used in fire stations and emergency response facilities to ensure continuous operation during fire incidents.

- Data Centers: Critical for maintaining uninterrupted power supply and data integrity in high-availability environments.

- Transportation: Installed in airports, train stations, and tunnels to safeguard public safety and infrastructure.

Conclusion

In the realm of fire protection within electrical installations, horstmann electronic 7 stands as a testament to innovation, reliability, and uncompromising safety standards. Throughout this comprehensive exploration, we have uncovered the multifaceted benefits and applications that make FP200 cable the preferred choice across various industries and environments.

From its robust construction designed to withstand high temperatures and mechanical stress to its adherence to rigorous international standards such as BS 7846 and EN 50200, FP200 cable exemplifies reliability under fire conditions. Its ability to maintain circuit integrity during critical moments ensures not only the safety of occupants but also the preservation of essential infrastructure.

Choosing FP200 cable represents a proactive investment in safety, mitigating the risks associated with fire hazards and providing peace of mind in both commercial and residential settings. While initial costs may be higher compared to conventional wiring, the long-term benefits in terms of durability, reduced maintenance, and compliance with regulatory requirements outweigh the initial investment.