Have you ever grabbed a candy bar just cause the wrapper was shiny? I remember being a kid standing in a small corner shop near my uncle’s house. Rows and rows of candy, but my eyes always went to the glossy ones, the ones that looked like treasure. That shine wasn’t by accident. That was metallized polyester film doing its magic.

So what does this film have to do with candy brands today? A lot more than most people think.

What even is metallized polyester film?

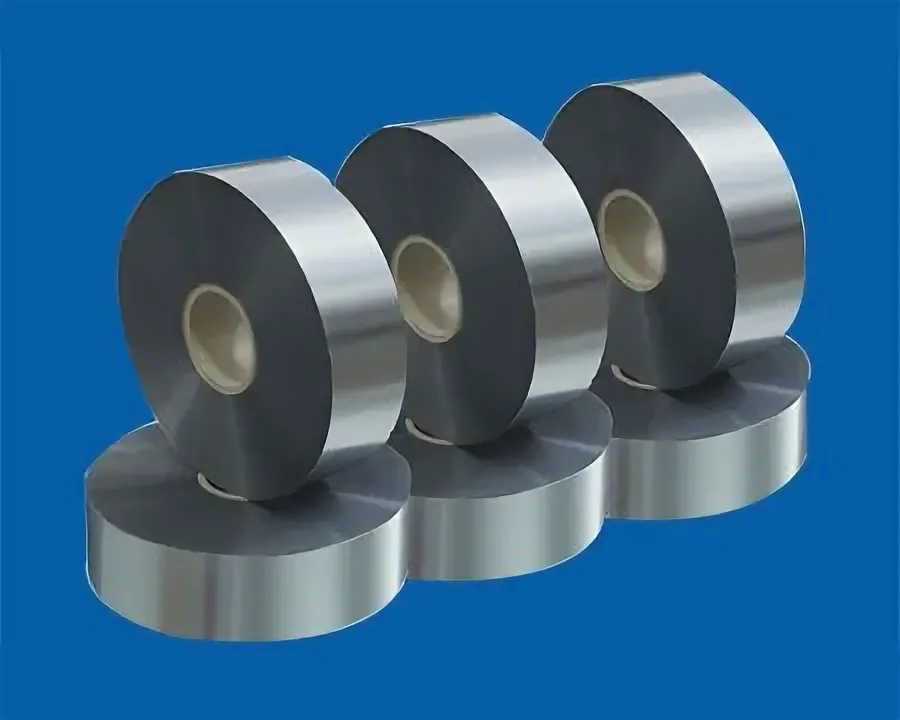

It’s a thin plastic film that’s coated with a layer of metal, usually aluminum. Sounds boring, right? But here’s the thing: it makes packaging shiny, strong, and keeps air and moisture out. For candy, that means longer shelf life and colors that pop out on the shelf.

Think about a chocolate bar. Without the right wrapper, it melts, it goes stale, it looks dull. With metallized polyester film, it feels like something premium, even if it’s just a $1 bar.

Why does the shine matter so much?

Ever notice kids grab the sparkly candy first? Shine means fun, excitement, and even quality in a lot of people’s eyes. I heard a story from a small sweet shop

excitement, and even quality in a lot of people’s eyes. I heard a story from a small sweet shop

owner in Manchester who said the candy wrapped in metallized polyester film outsold the plain plastic wrapped ones by almost double. People buy with their eyes before they buy with their taste buds.

That shiny look isn’t just for kids either. Adults associate metallic finishes with “special edition” or “luxury.” So when a brand wants to stand out, this film gives them that edge without costing too much.

Does it really keep candy fresh?

Yes, and that’s another huge reason brands use it. One chocolatier in Birmingham told me their seasonal truffles used to get complaints about tasting stale after a week on the shelf. Once they switched to metallized polyester film, the truffles kept their snap and flavor way longer. Less waste, more happy customers.

The film basically blocks oxygen and moisture. Candy doesn’t like air, trust me. Sugar can get sticky, and chocolate turns white and chalky. This film fixes that problem in a simple way.

How can candy brands use the film to tell their story?

Here’s where it gets fun. Metallized polyester film isn’t just shiny silver. It can be printed with bold colors, patterns, and even holographic effects. Imagine a holiday edition candy bar with snowflakes that shimmer, or a summer gummy bag that sparkles like sunlight on water.

A friend of mine in Leeds runs a small fudge company. They used plain, clear bags for years, but last Christmas they tried metallized polyester film with a gold finish and a little window to peek at the fudge. Sales jumped. People said the packaging felt gift-worthily.” Same fudge, different wrap, whole new level of brand.

Is it only about looks?

Not really. Confectionery brands are under pressure about sustainability, too. People ask, “Is metallized polyester film eco-friendly?”

Here’s the truth: it’s not the greenest option, but recycling tech is getting better. Some regions in the UK have testing facilities that can separate the layers of film and recycle them properly. Plus, the film actually reduces food waste by keeping candy fresh longer, which is another angle brands can talk about.

Some brands even use thinner versions of the film, cutting down plastic use without losing the shiny effect. It’s not perfect, but it’s better than candy going bad and ending up in the bin.

What about the local candy shop? Do they need this, too?

Totally. It’s not just for big names like Cadbury or Mars. Local shops can use metallized polyester film to compete. Think about a seasonal sweet fair in Liverpool or a farmer’s market in Glasgow. If two stalls are selling toffee, the one with the bright, shiny packaging is going to catch more eyes.

And it doesn’t take a huge budget. Small runs of printed metallized film are possible now. I’ve seen shops in Sheffield ordering custom rolls just for Easter eggs or Halloween candy bags. The investment pays back quickly when customers pick their sweets first.

Is it expensive for brands to switch?

Not as much as most think. One confectioner in London told me they thought metallized polyester film was only for “the big guys.” But once they checked, they found suppliers offering smaller orders that fit their budget. They even saved money because the candy lasted longer on shelves, so less product got wasted.

Can it handle seasonal problems?

Yes, and this is a big one for confectioners in the UK. Summer heat waves melt chocolate fast. Winter damp makes sugar sticky. Metallized polyester film helps fight both. It keeps moisture out in the cold months and adds a protective layer during hot spells.

One shop owner in Brighton said during the July heat wave last year, their wrapped chocolate bars held up way better than the unwrapped or thin plastic wrapped ones. Customers noticed too. They said, “Your chocolate doesn’t melt as badly as the others.” That kind of word of mouth is gold for small businesses.

So what’s the real takeaway here?

Metallized polyester film is more than just shiny plastic. For the confectionery industry, it’s a tool:

-

Keeps candy fresh longer

-

makes brands stand out on the shelf

-

works for both big and small companies

-

helps handle seasonal challenges

-

gives room for creativity in branding

At the end of the day, candy isn’t just about taste; it’s about the experience. Shiny wrappers make people feel like they’re getting something special. That feeling drives sales, builds loyalty, and gives even the smallest sweet shop a chance to look like a big player.

So next time you see that shiny chocolate bar calling your name, remember, it’s not just candy. It’s smart packaging, and metallized polyester film is the secret behind it.

Also Read: Stainless Steel Sheet

FAQs

What is metallized polyester film?

Metallized polyester film is a thin plastic film, usually made from PET, that’s coated with a very fine layer of metal like aluminum. It looks shiny and reflective, and it’s used a lot in packaging to keep food fresh and make products stand out on shelves.

What is the process of metallized film?

The process is called vacuum metallization. The polyester film goes into a vacuum chamber where the aluminum is heated until it turns into vapor. That vapor sticks to the film and makes a thin, shiny layer. This gives the film both its metallic look and its barrier protection against air and moisture.

What is polyester film used for?

Polyester film is super versatile. It’s used in food packaging, candy wrappers, chip bags, insulation, labels, and even in electronics. When it’s metallized, it adds that shiny look and better protection, which makes it very popular in the confectionery industry.

Metallized polyester film price in Pakistan

The price can vary depending on thickness, quality, and supplier. On average in Pakistan, metallized polyester film ranges from about PKR 350 to PKR 600 per kg for standard grades, but prices can change based on market demand and order size. Wholesale suppliers may offer better rates if you’re buying in bulk.