From agriculture to construction and manufacturing industries, a vast range of fluid transfer systems are employed. The suction pipes serve an important function for the liquid that is drawn or transferred from one place to another without any loss or blockage. The use of appropriate suction pipes enhances efficiency during operations, minimizes downtimes, and makes sure fluid movement is optimized. This article explains the efficient fluid transfer suction pipes and why they are important, including various aspects such as advantages and transfer pipes, which are complementary to delivery sections.

Explaining the Function of Suction Pipes

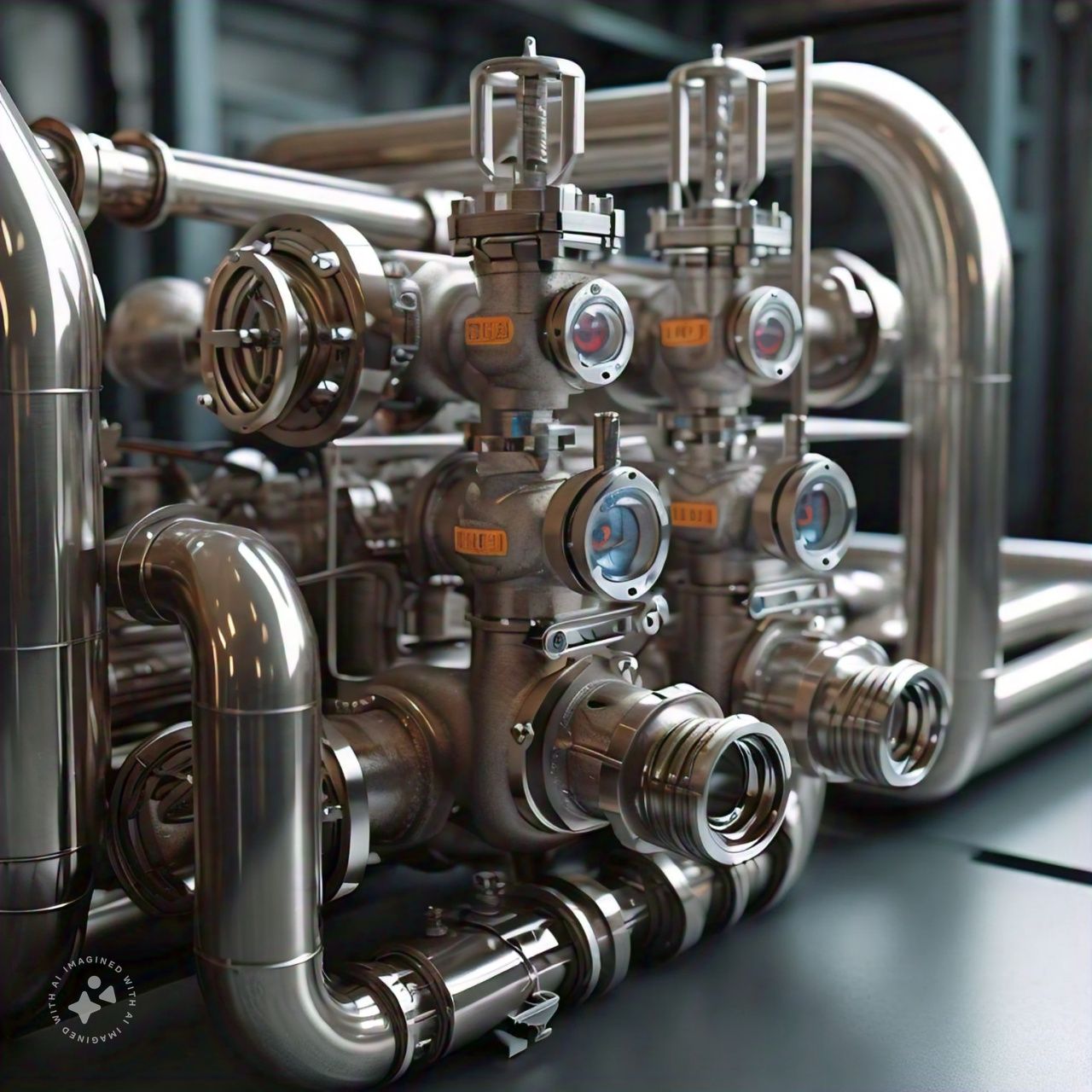

Suction pipes have a specific function, which is to draw fluids into the system that is operating at a vacuum pressure to assist in transferring water or fluids from a specific point. These pipes are structural components of pumps and other fluid-carrying devices. The aspects of their flexibility and durability are also critical in order to ensure smooth runs in different operations. These and the rest of the design features of suction pipes are called performance characteristics, and the proper ones ensure the desired efficiency and lifetime of the device.

Types of Suction Pipes

There are different types of suction pipes available, each suited for different applications. Relatively common options include rigid PVC pipes, hose pipes or flexible hoses, and rubber-reinforced pipes. The choice of material and design depends on the nature of the fluid, the pressure required, and the surrounding conditions. For instance, PVC pipes are used in linings of low-pressure systems, while elastomeric suction hoses are applicable in applications that require high flexibility and movement. On the other hand, reinforced rubber pipes are preferred for industrial applications because of their strength and durability.

Factors to Consider When Choosing Suction Pipes

When choosing suction pipes intended for water and fluid transfer, there are several considerations that must be made. These include pipe material, diameter, degree of flexibility, and the pressure rating of the system. Material choice is very important; for instance, there are some types of liquid, such as chemicals or hot water, that require special pipes designed for higher temperatures and resistance to corrosion. The pipe size of a suction pipe must conform to the flow rate of the system; this is done to ensure maximum efficiency in the suction process. Moreover, the elasticity of the pipe is very necessary for the systems that are subjected to vibrations or installed in congested areas.

Significance of the Suction Pipes in Fluid Transfer Systems

Suction pipes are needed in ensuring proper water and fluid transfer systems operability. They aid in providing constant liquid flow, which diminishes chances of air incorporation into the system, which may lead to pump cavitations or unfavourability. The right suction pipes also aid in preventing the loss of fluid as well as ensuring the efficient movement of liquids from one location to another, hence making the system perform better. Suction pipes reduce the chances of leakage and blockage, hence increasing the lifespan of the whole fluid transfer system.

Delivery Pipes and Their Complementary Role

There are, however, delivery pipes that work in conjunction with suction pipes to perform the specific focus of the fluid transfer system. As the name suggests, delivery pipes are more rigid than suction pipes and vice versa. Their use ensures that once the fluids have been drawn in, they will be easily delivered to the appropriate location, which may be a storage tank, an irrigation system, or even an industrial appliance. To have such a seamless flow of fluids in one system, the appropriate delivery pipes to go with the suction pipes are selected.

Identifying the Right Suction Pipes for Your Purposes

To make the most suitable choice of suction pipes, it is vital to consider the needs of the application. In the case of agricultural irrigation systems, it is possible that lighter and more flexible suction pipes are preferred. However, in industrial applications, reinforced suction pipes that are more heavy-duty may be necessary. It is vital to establish a good relationship with an accredited supplier who can sell proper suction pipes and advise on the material suited to the fluid being transferred. Factors influencing the suction and delivery pipes’ performance relationship must also be established and maintained for the best performance delivery.

Final Ideas

All these factors constitute the best suction pipes that are vital in proper transfers of water and fluid from one location to another. It is through the understanding of what the suction pipes operations are in a system, evaluation and assessment of the factors that influence plumbing elements, and usable delivery pipes that businesses and industries ensure safe fluid transfer activities. Officially from the supplier, quality suction pipes should be purchased and always put into system use as they enhance operation and increase the useful life of the entire working system, leading to increased and relatively lower costs of operations. Although they will be sold for domestic, agricultural, or industrial applications, suction pipes are a worthwhile investment.